NIMS Industrial Technology Maintenance

The National Institute for Metalworking Skills (NIMS) has endorsed Amatrol’s eLearning as the preferred curriculum for its Industrial Technology Maintenance (ITM) credentials. These credentials were created to fill the growing number of unfilled jobs in industrial maintenance with individuals having proven skill sets.

NIMS training is widely recognized for the qualified employees produced through their certification programs and Amatrol is the world’s leader in skills-based interactive technical learning. Amatrol’s hands-on, skills-focused interactive technical training include an on-the-job training guide to aid businesses in accommodating NIMS’ credentials to real-world training experiences.

To learn more about how Amatrol’s eLearning prepares learners for NIMS training certifications, check out the following article: NIMS Certifications Pave the Path to a Successful Career in Industry by Duane Bolin.

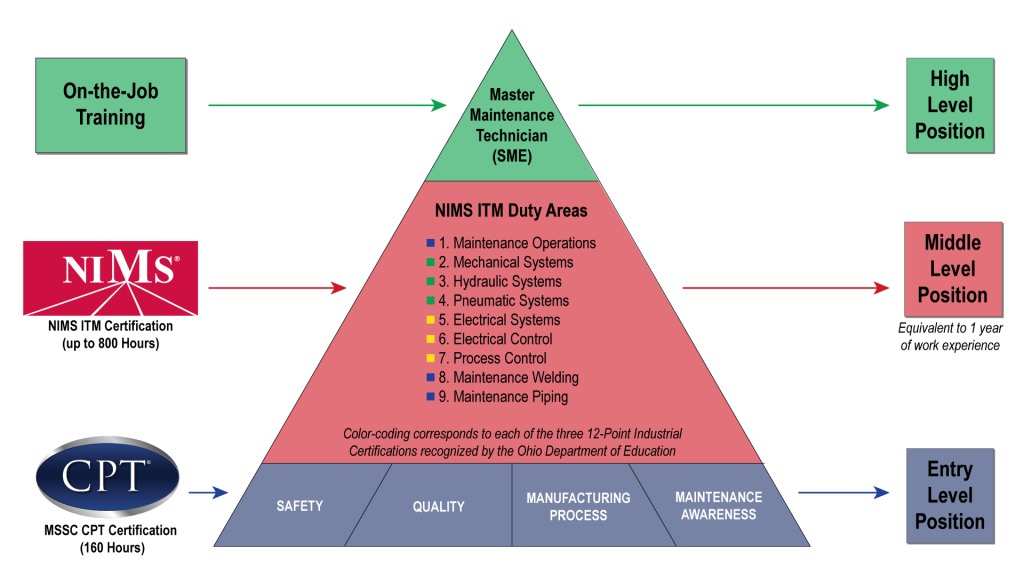

NIMS Training Stackable Credentials: Learn and Earn at the Same Time!

The ITM certification features nine stackable certifications, so you can attain your certificate in any of the 9 Duty Areas, such as Maintenance Operations, and use it to find a job while you complete additional certifications. The nine stackable certifications are available in:

Duty Area 1: Maintenance Operations

Duty Area 1 Summary

Duty Area 2: Basic Mechanical Systems

Duty Area 2 Summary

Duty Area 3: Basic Hydraulic Systems

Duty Area 3 Summary

Duty Area 4: Basic Pneumatic Systems

Duty Area 4 Summary

Duty Area 5: Electrical Systems

Duty Area 5 Summary

Duty Area 6: Electronic Control Systems

Duty Area 6 Summary

Duty Area 7: Process Control System

Duty Area 7 Summary

Duty Area 8: Maintenance Welding

Duty Area 8: Summary

Duty Area 9: Maintenance Piping

Duty Area 9 Summary

Learn how these stackable credentials correspond to 12-Point Industrial Certifications recognized by the Ohio Department of Education:

Duty Area 1: Maintenance Operations (32 eLearning Modules)

- Adhering to safety, health, and environmental rules and regulations

- Operating and monitoring a machine

- Interpreting machine operation and maintenance documentation and technical drawings

- Performing machine maintenance procedures, preventative maintenance, and predictive maintenance

- Selecting and safely using of proper hand tool for a task

- Moving, handling, and storing materials and equipment

- Selecting systems troubleshooting methods

- Learning systems that can add hands-on skills to Duty Area 1 topics include:

Duty Area 2: Basic Mechanical Systems (20 eLearning Modules)

- Adhering to mechanical power transmission safety rules

- Using dimensional measuring tools

- Installing and aligning shaft couplings, belt drives, chain drives, gear drives, and pillow block bearings

- Identifying lubrication points, selecting lubricant, and applying lubricant to a machine

- Troubleshooting power transmissions

- Learning systems that can add hands-on skills to Duty Area 2 topics include:

Duty Area 3: Basic Hydraulic Systems (20 eLearning Modules)

- Adhering to fluid power systems safety rules

- Interpreting basic fluid power schematics

- Starting up and shutting down a hydraulic system and adjusting system pressure

- Adjusting hydraulic actuator speed using a flow control valve

- Servicing hydraulic fluid and a hydraulic filter

- Installing hydraulic conductors and installing and testing components in a basic hydraulic circuit

- Troubleshooting a basic hydraulic circuit

- Learning systems that can add hands-on skills to Duty Area 3 topics include:

Duty Area 4: Basic Pneumatic Systems (14 eLearning Modules)

- Adhering to fluid power systems safety rules

- Adjusting pneumatic system branch operating pressure using a regulator and pneumatic actuator speed using a flow control valve

- Servicing a pneumatic filter and pneumatic lubricator

- Installing pneumatic conductors

- Starting up and shutting down a reciprocating air compressor and adjusting operating pressure

- Installing and testing components in pneumatic circuits

- Learning systems that can add hands-on skills to Duty Area 4 topics include:

Duty Area 5: Electrical Systems (35 eLearning Modules)

- Adhering to electrical power and control systems safety rules

- Interpreting electrical control and power schematics

- Adjusting limit switches and electronic sensors

- Measuring voltage, current, and resistance in an electrical circuit

- Selecting, installing, and testing fuses and circuit breakers

- Installing and testing AC and DC electric motors, electrical relay control components and circuits, and electro-fluid power components and circuits

- Testing and repairing a machine’s electrical ground

- Troubleshooting an electrical motor relay control circuit and a solenoid-operated fluid power relay control circuit

- Replacing electrical control wiring using terminal and solder attachments

- Testing and replacing transformers

- Learning systems that can add hands-on skills to Duty Area 5 topics include:

Duty Area 6: Electronic Control Systems (27 eLearning Modules)

- Adhering to electronic and control systems safety rules

- Connecting and testing a DC power supply

- Installing and testing a solid-state relay, analog electronic sensors, and basic PLC components

- Installing and operating and AC variable frequency drive

- Transferring programs to programmable controller using a PC

- Creating a basic PLC ladder-style program

- Troubleshooting PLC and controlled components

- Learning systems that can add hands-on skills to Duty Area 6 topics include:

Duty Area 7: Process Control System (11 eLearning Modules)

- Adhering to process control systems safety rules

- Reading and interpreting process control documentation

- Calibrating and testing analog sensors and final control elements

- Installing and operating a basic controller

- Learning systems that can add hands-on skills to Duty Area 7 topics include:

Duty Area 8: Maintenance Welding (7 eLearning Modules)

- Adhering to welding safety rules

- Using an acetylene torch

- Explaining welding theory, equipment, and selection process

- Preparing parts to be welded

- Using a SMAW Welder to make basic welds on flat stock

- Inspecting welds

- Using a plasma cutter to cut flat stock

- Learning systems that can add hands-on skills to Duty Area 8 topics include:

Duty Area 9: Maintenance Piping (5 eLearning Modules)

- Adhering to piping system safety rules

- Interpreting basic piping schematics

- Identifying and selecting correct material

- Measuring and preparing material

- Installing piping systems

- Learning systems that can add hands-on skills to Duty Area 9 topics include: