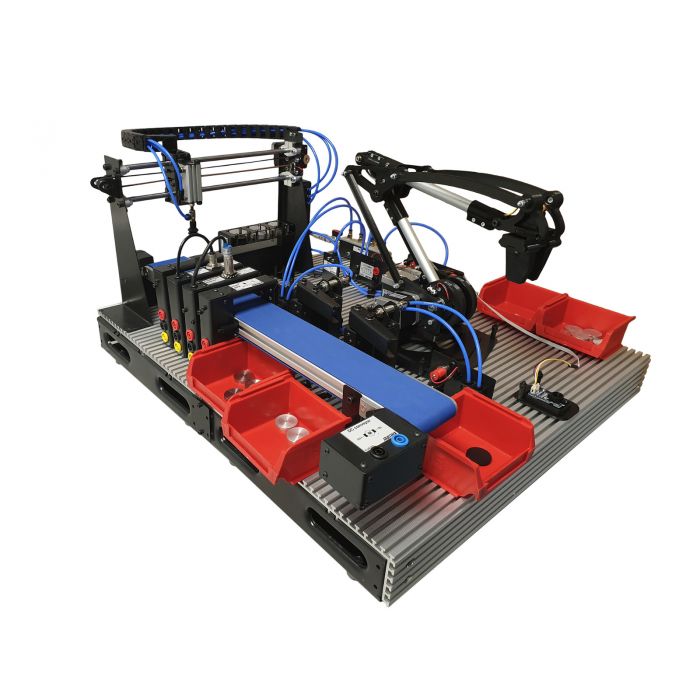

Smart Factory

![]()

The Automatics Smart Factory provides students with hands-on experience of various processes and technologies commonly used in manufacturing and Industry 4.0 principles. These include conveyor systems, sensing systems, pneumatic pick-and-place technology, DC motor drivers, and stepper motor drivers. The factory uses colored discs made from plastic and other materials. A conveyor belt transports these discs into the factory, where user-programmed sensors sort them into different rejection bins. Some discs are picked off the conveyor by a suction device and a stepper motor-controlled gantry sorts them into appropriately colored containers. The Smart Factory is fully self-contained and can be stored in one of our standard trays. It is compatible with Siemens (or other brand) 12V or 24V PLCs.

Key Features

- Gantry system with three pneumatic inputs

- Gantry driven by stepper motor driver

- Conveyor system 60mm x 500mm in size

- DC and Stepper motor drives

- Inductive and Capacitive sensors

- 2 laser light gates with rejection components

- Pneumatic pick and place technology

- Robot arm integration gives powerful Industry 4.0 learning solution

Learning Objectives

- Factory control and automation systems

- Software design for automation

- DC motor and stepper drives

- Conveyor and gantry systems

- Vacuum pick and place systems

- Component sensing and sorting

- System design with more than one controller.

OVER 35 YEARS OF SERVICE

Providing insight, selection, installation, and ongoing support of the latest educational and career technology.

Request a Quote Learn More About MatrixFor more information or to contact Buckeye Educational Systems, your Authorized Matrix Reseller, call 800.522.0460 or email info@buckeye-edu.com